| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : WINCOO

Model Number : MSHW-I

Certification : CE

Place of Origin : CHINA

MOQ : 1 unit

Price : USD 5000~12000

Payment Terms : L/C,D/A,D/P,T/T,Western Union

Supply Ability : 230 Set/Year

Delivery Time : 45 working days

Packaging Details : Export package

Model NO. : MSHW-I

Keywords : Tank Girth Welding Machine

Plate Thickness : 8~45mm

Plate Material : Carbon Steel, Stainless Steel

Welding Process : Saw

Transport Package : Container

Specification : SGS, ISO9001, CE

Trademark : WINCOO

Origin : Nanjing, China

HS Code : 851531900

Cooling Way : Water Cooling

Control : Semi-Automatic

Style : Hanging

Frequency Range : Intermediate Frequency

Electric Current : Inverter

Type : Continuous Seam Welder

Customization : Available | Customized Request

The MSHW-I is a robust, rail-mounted automated welding system specifically engineered for high-efficiency horizontal (girth) welding of large-diameter vertical storage tanks, pressure vessels, and silos. Utilizing proven crawler technology, it delivers consistent, high-quality welds around the circumference of the tank shell during construction. Ideal for shipyards, tank fabrication yards, and heavy industrial construction sites, it significantly boosts productivity while reducing manual labor requirements and improving weld integrity.

Key Specifications:

| Welding Process | Submerged Arc Welding (SAW) or Flux-Cored Arc Welding (FCAW) capable |

| Tank Diameter Range | 6 meters (20 ft) to 50 meters (164 ft)+ |

| Travel Speed | 150 - 750 mm/min (6 - 30 in/min), continuously adjustable |

| Drive System | Dual heavy-duty crawler tracks with magnetic or mechanical clamping |

| Power Source Compatibility | Standard 415V/480V 3-phase; interfaces with common SAW/FCAW power sources & wire feeders |

| Wire Feed Speed | Compatible with standard feeders (e.g., 100 - 1500 ipm) |

| Welding Head Control | Manual vertical & horizontal adjustment; optional oscillation (up to ±50mm / ±2") |

| Control System | Basic digital control panel for speed, voltage, wire feed (remote control optional) |

| Weight | ~150 kg (330 lbs) |

| Track Length | Modular sections (e.g., 1.5m/5ft) for easy transport & setup |

Key Features:

1, Exceptional Stability: Heavy-duty crawlers and rigid frame ensure stable travel on vertical surfaces, even on slightly uneven plates.

2, High Productivity: Dramatically faster than manual welding, enabling continuous welding of long seams.

3, Consistent Weld Quality: Precise speed control and stable arc lead to uniform bead appearance and improved mechanical properties.

4, Reduced Labor & Fatigue: Requires only 1 operator for setup and monitoring, eliminating strenuous overhead welding.

5, Durability: Rugged construction for harsh industrial environments.

6, Ease of Setup: Modular track system simplifies assembly around the tank circumference.

7, Versatility: Handles common shell materials (carbon steel, low-alloy steel) and thicknesses (e.g., 6mm to 40mm / 0.25" to 1.6").

8, Safety: Reduces worker exposure to welding fumes (especially with SAW) and arc flash at height.

Application Scenarios:

a. Fabrication of large API 650 / API 620 / EN 14015 standard aboveground storage tanks (ASTs) for oil, chemicals, water, or LNG.

b. Construction of power plant water storage tanks and wastewater treatment digesters.

c. Girth welding of large diameter process vessels and pressure tanks in refineries and chemical plants.

d. Erection of grain silos and cement storage silos.

e. Shipbuilding - sections of large hulls or storage tanks within vessels.

|

|

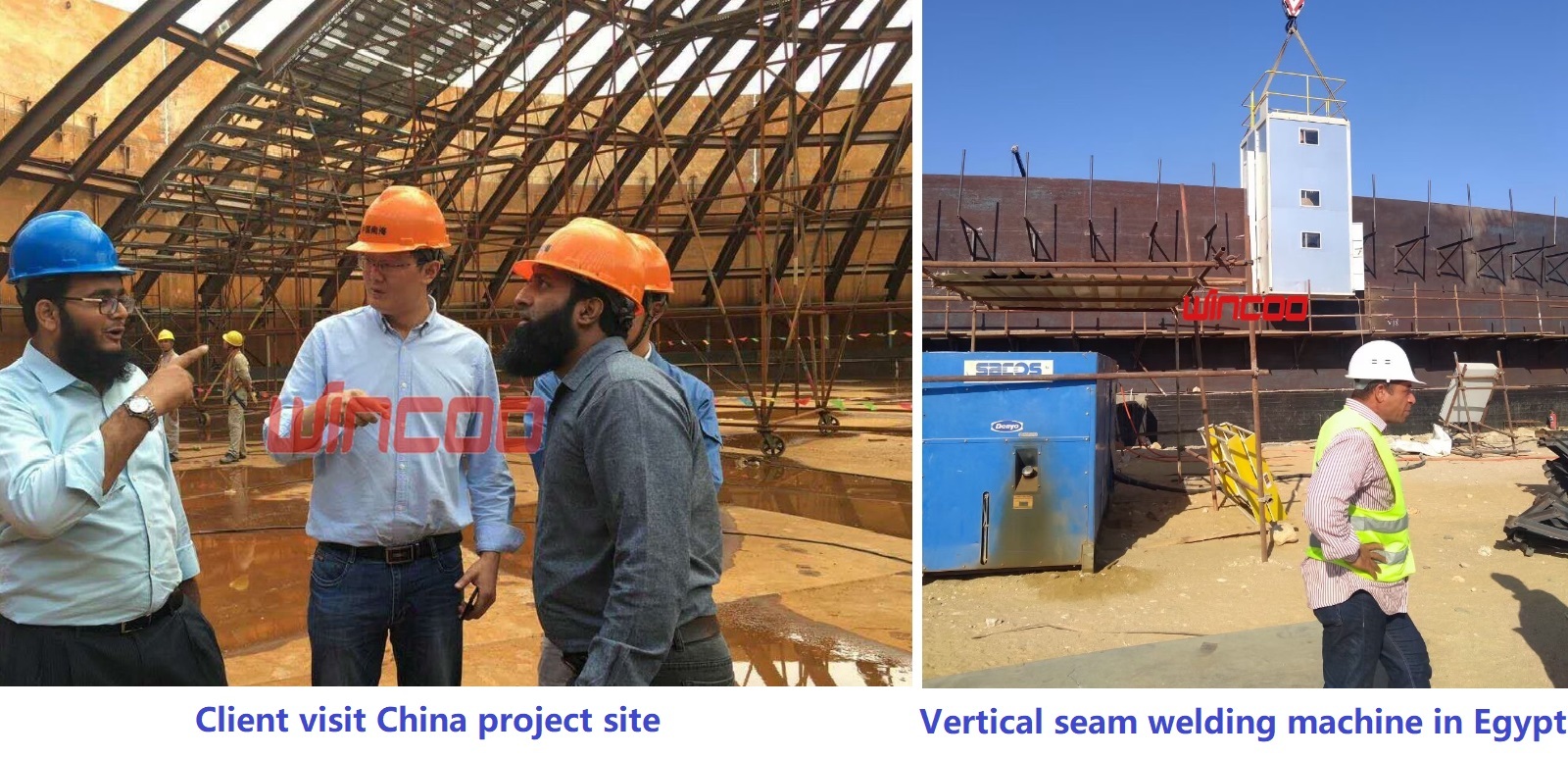

Standard Heavy-Duty Horizontal Tank Welding Machine Images |